SAP INTEGRATED BUSINESS PLANNING is a cloud-based supply chain planning solution that makes supply chains more visible and manageable for companies of all sizes.

Building supply networks that are resilient to risk is a major task that is necessary for modern enterprises.

Supply chains are becoming more intricate and linked in today’s international economy, which leaves them open to interruptions from a range of factors, including natural disasters, unstable political environments, and economic downturns. Companies must act proactively to create supply networks that are resilient to risk so they can survive these interruptions.

SAP is assisting companies in creating supply chains that are robust to risk by offering solutions that link their whole supply chain, giving them real-time visibility into it, and empowering them to make smarter decisions regarding it.

For all facets of supply chain planning, it offers a single platform that includes:

- Sales and operations planning (S&OP)

- Forecasting And Demand

- Inventory Planning and Optimization

- Response and Supply Planning

- Demand-driven replenishment

- Supply Chain Visibility

Sales and operations planning (S&OP):

Real-Time Planning: Supply and demand must be balanced, planning must be integrated with operations and finance, and execution must be connected to long- and mid-term goals.

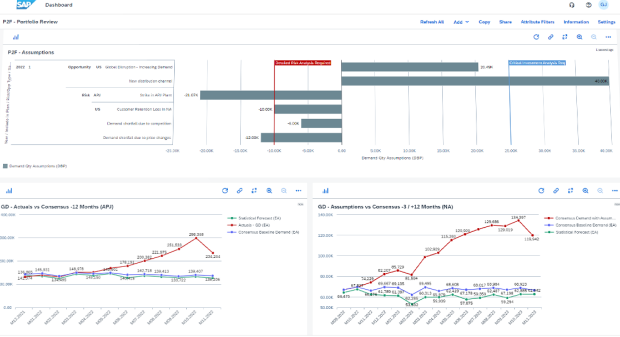

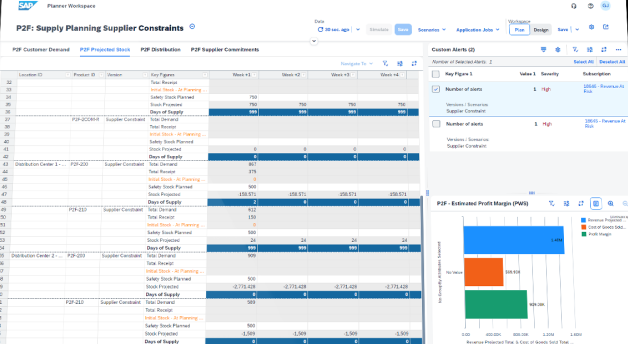

Simulation And Comparison Of Scenarios: Make quick, well-informed decisions that reduce risk by comparing scenarios and conducting what-if analyses on changes in supply or demand.

Collaboration: Improve collaboration and efficiency in the planning process by dismantling operational and planning silos.

Performance Monitoring: Check for future operational and strategic plan misalignment by comparing actual performance to the plans.

Forecasting And Demand:

Demand Planning: Collaborate to develop precise demand plans by combining a variety of demand signals with statistical projections.

Advanced Demand Sensing: Improve short-term projections to promote better fulfillment and a decrease in inventory.

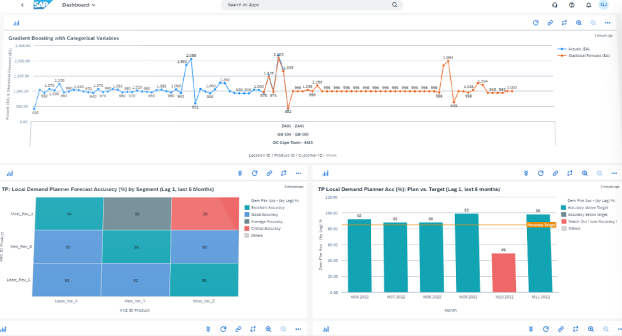

Robust statistical models: Make use of advanced forecasting algorithms along with pre and post-processing algorithms and machine learning.

Time-Series Analysis: Sort products according to past trends, then choose algorithms according to that sorting.

Inventory Planning and Optimization:

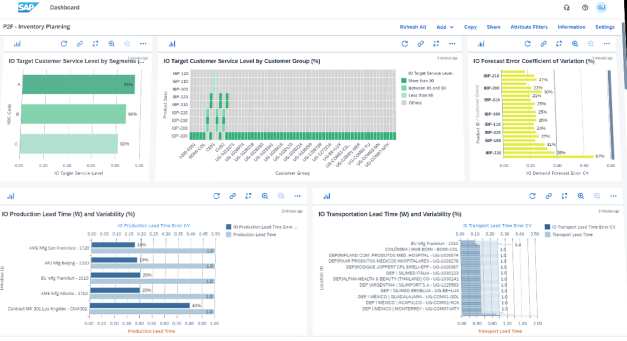

Multistage inventory optimization: Using multi-echelon inventory optimization, you can buffer supply chain risk and uncertainty by using less inventory.

Robust statistical models: Offer a great deal better than calculations found in textbooks using tested algorithms.

Forecast error management: To support your demand and supply chain, provide a buffer against forecast error and other demand-side uncertainties.

Embedded analytics: See your supply chain network to quickly learn what drives inventory.

Response and Supply Planning:

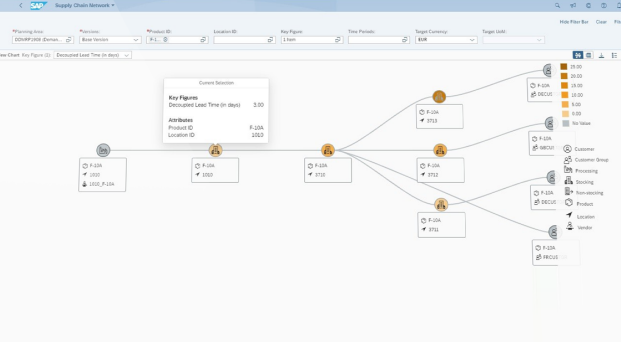

Multi-level planning: To cover the whole supply chain network, use multilevel bills of material and cross-location modeling.

Supply planning: Create a tactical supply plan by applying an optimization technique, either heuristic-based or unconstrained.

Rough-cut planning: Construct a tactical rough-cut capacity plan while taking material and capacity constraints into account at the same time.

Response management: Establish a supply plan that is either operational or order-based, and use prioritization rules to control order allocations and re-promotions.

Demand-Driven Replenishment:

Smooth material and information flow: Stop the bullwhip effect in your supply chain and reduce anxiety in the supply chain.

Replenishment based on actual demand: Reduce the effect that inaccurate forecasts will have on your replenishment plan.

Calculation of decoupled inventory buffers: To calculate the size of inventory buffer zones, use forecasts for future or past material consumption.

Supply chain resilience: Utilise supply chain decoupling points to mitigate supply and demand uncertainty.

Supply Chain Visibility:

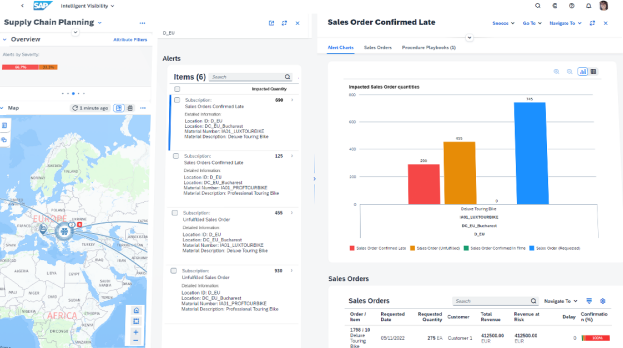

Intelligent visibility into your supply chain: Think of the supply chain of your business as a network with performance-affecting exceptions.

Simulation and comparison scenarios: For what-if analysis, run simulations of changes in supply or demand, and compare scenarios to make quick, well-informed decisions.

Event-driven exception management: Customer alerts help you quickly identify problems by giving you context and priority information.

Supply network collaboration: For simpler and quicker planning, collaborate with manufacturers who are exporters and suppliers.

Benefits Of SAP Integrated Business Planning (SAP IBP)

Improved visibility: All supply chain data has a single source of truth thanks to SAP IBP. This aids companies in better understanding their supply chains and seeing possible issues before they become serious ones.

Increased efficiency: SAP IBP automates many manual planning tasks, which can free up time for planners to focus on more strategic work.

Reduced costs: Businesses can lower transportation, inventory, and other supply chain costs with the aid of SAP IBP.

Improved customer satisfaction: Businesses that use SAP IBP to enhance their capacity to meet customer demand may see an increase in customer satisfaction.